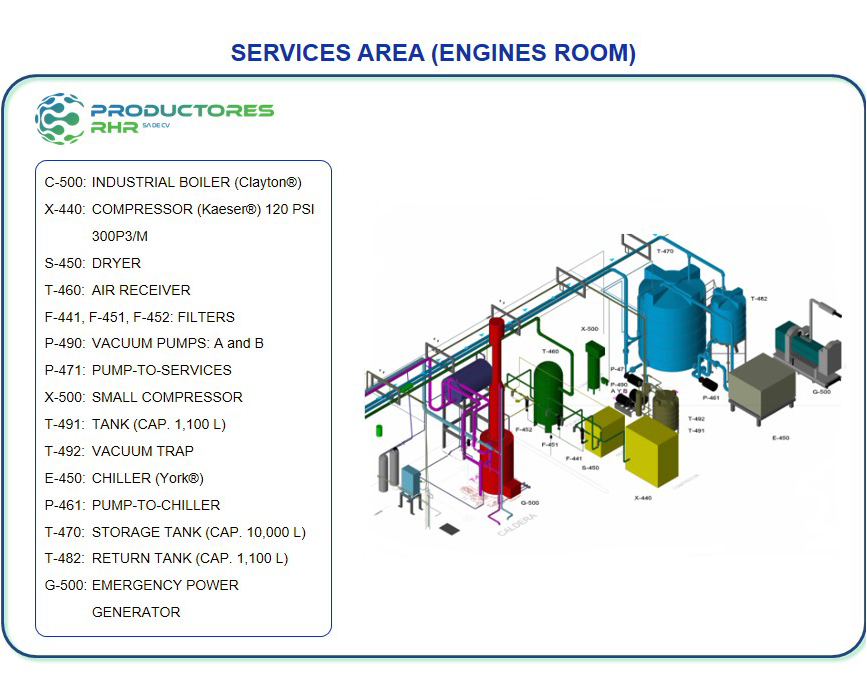

SERVICE AREA

MACHINES AREA:

This area is located on the exterior part of the plant, built up with equipment that distributes the required services to all of the work areas.

There is a Clayton® vapor generator that covers the vapor demand for the sterilization of our bioreactors and piping. The equipment relies on an integrated water softening system for the supply to the generator; at a work pressure of 7 Kg/cm2. The equipment is fully automated.

We rely on a Kaeser® compressor for the distribution of air to the production area. For the distribution to the laboratories we have a less robust equipment (Ingersoll Rand®).

To maintain the refrigerant at the required temperature, we count on a chiller unit through air, with a capacity of 10 MT, built into a 10,000 L balance tank and thermal isolated to preserve the refrigerant’s temperature.

In order to provide vacuum to the chemical extraction area and laboratories, we have a vacuum pump integrated to an air receiver and a cooling system. It is worth pointing out that all of these equipments are automated and integrated to the required distribution pipes.

ELECTRICAL FACILITIES:

The complex has a three-phase transformer, 22,860 median tension, 440/254 volts and delta-star connections, as its own substation as well. Additionally, it has a fully automated 100kW diesel emergency plant, 440/254 volts, 3 phases and 4 threads. It becomes functional 5 seconds after detecting a failure on the electrical supply.